In the early days of a new technology build, getting your prototype working as quickly as possible often takes precedence over long-term hardware planning. And that makes sense, when you’re trying to prove an idea, time is the enemy, not cost.

But here’s where many R&D projects run into trouble: the hardware decisions made during early development don’t always translate well into production. What works for a minimum viable product (MVP) often doesn’t work when you need to build 100, 500, or 1,000 units, reliably, affordably, and with guaranteed part availability.

For engineers and program leads managing the transition from R&D to production, this handoff is where projects succeed or stall.

Let’s break down what changes between the two phases, and why smart hardware planning must account for both.

In R&D: Speed Wins, Even if It Costs More

Early-stage R&D is driven by rapid iteration and experimentation. You're focused on:

Early-stage R&D is driven by rapid iteration and experimentation. You're focused on:

- Proving the concept

- Testing feasibility

- Meeting funding or internal milestones

- Demonstrating basic functionality (even if it's a bit hacked together)

At this stage, hardware decisions are often made based on what’s available now. You may grab a commercial off-the-shelf system that meets the performance spec, even if it’s overkill. You might overengineer just to avoid delays: more CPU, more GPU, more memory, because why risk being underpowered?

As Radeus Labs CEO Juliet Correnti points out:

"When the focus is on R&D, hardware might not matter as much. You’re trying to get an MVP, and sometimes that means the cheapest way possible, or just buying what you can get your hands on. It might be all-inclusive, even overengineered, money is no object if it gets the job done fast.”

And that can work, for now.

But this mindset becomes a liability when your prototype graduates to production.

In Production: Cost, Quality, and Longevity Rule

Once your project shifts from “Can we build this?” to “How do we build this at scale?” the entire calculus changes.

In production environments:

- Every extra dollar spent matters when you’re building at volume.

- Component availability over time becomes a risk factor.

- Reliability and support become non-negotiable.

- Manufacturability, not just functionality, is the priority.

The exact hardware you used for your prototype might now be:

- Discontinued or hard to source

- Too expensive for scaled deployment

- Lacking the right certifications

- Incompatible with real-world environmental requirements (e.g., size, heat, vibration)

This is where hardware decisions made in haste during R&D come back to bite. If no one was thinking about production early on, your team may be forced to redesign, revalidate, and retest, adding months of delay and unnecessary cost.

Avoiding the Disconnect: What Experienced Hardware Partners Do Differently

The transition from prototype to production doesn’t have to be painful, if your hardware partner thinks beyond the demo.

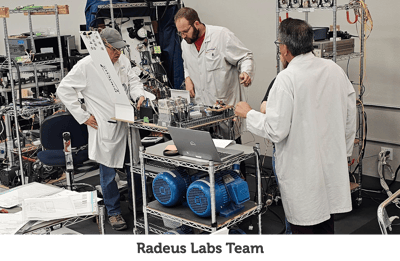

At Radeus Labs, for example, engineers don’t just spec for today’s build. They think about what’s available six months or a year from now. They consider:

- Will this vendor support this board long enough?

- Will this GPU still be in production when the customer needs a second or third unit?

- Is this component qualified for field use, or just the lab?

That’s what sets apart engineering-first hardware providers from transactional vendors. “We’re not just selling the customer a product for today,” explained one Radeus team member. “We’re selling them something that works today, and tomorrow, and five years from now.”

A Better Approach: Design With Production in Mind from Day One

The best R&D teams take a dual-track approach: move fast in the lab, but always keep one eye on the future. That means:

- Choosing components with long-term availability

- Avoiding vendors with unpredictable supply chains

- Validating parts not just for performance, but for reliability

- Documenting choices early so production teams aren’t starting from scratch

If your engineering partner can’t help you think through these factors, you’re likely to hit a wall during scale-up.

R&D to Production Isn’t a Line, It’s a Bridge

There’s no clean handoff between prototyping and production. It’s not a line you cross. It’s a bridge, and that bridge needs to be engineered with care.

Fail to account for cost, lifecycle, and integration? You’re stuck redesigning.

Plan with both phases in mind? You get to market faster, cheaper, and with fewer surprises.

Ready to Make Smarter Hardware Decisions, From R&D Through Production?

If you’re working on an advanced tech project where prototyping is just the beginning, our new guide can help.

Download From Hardware to Production: Essential Hardware & Support Considerations to learn how to:

- Choose hardware that scales from prototype to deployment

- Avoid component obsolescence traps

- Reduce costly redesigns between phases

- Balance short-term speed with long-term sustainability

Get tips that help you build systems that last, without compromising on innovation.

![[NEW GUIDE] A Step-by-Step on Getting 3dB Beamwidth Right in Real-World Teleport Operations](https://blog.radeuslabs.com/hubfs/%5BNEW%20GUIDE%5D%20A%20Step-by-Step%20on%20Getting%203dB%20Beamwidth%20Right%20in%20Real-World%20Teleport%20Operations.png)

.png?width=200&height=277&name=1%20(2).png)

AIAA SciTech 2026

AIAA SciTech 2026